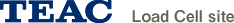

The TD-9000T is a digital indicator for load management that supports two inputs, load (load cell) and stroke (displacement gauge).

High-speed A/D conversion of 25,000 times/sec and equipped with a 4.3-inch touchscreen monitor in DIN1/4 (92 x 92) size. While being high-end, it is a high-performance model that realizes a low price.

Waveforms during measurement can be checked in real time. Widely usable from daily monitoring to verification of processing data.

NPN (sinking) and PNP (sourcing) are the terms to show the type of output by the transistor.

A transistor is an element that controls the flow of electricity.

It is used in output of sensors and output unit of PLC.

Features: Used mainly in Japan and the U.S.A.

It is also called sink output because the current flows toward the control device (sensor).

Advantage: No damage to transistor elements even if short-circuited to ground immediately after transistor output

Features: Used mainly in Europe.

It is also called source output because the current flows out from the control device (sensor).

Advantage: Input devices do not operate even if the immediately after output of the transistor is shorted to ground → greater safety for the operator

The end reference function is a method of judgment in which the displacement at the end of measurement is set as the reference (0) and the starting point of measurement is set as a minus value.

The scale shift & zoom function allows you to expand the selected area to full scale.

A 4.3-inch wide touchscreen monitor is mounted on a general-purpose 92 x 92 mm panel mounting hole size.

Tap the image on your iOS or Android device to use it.

If you are browsing on a PC, use the QR code below.

* Check here for the operating environment and operation method of AR.

The indicator value display allows to check the real-time load value and setting conditions, and also the waveform display mode allows to make OK/NG judgment on the waveform in real time.

※When the unit is turned on, the screen last open when it was turned off reopens (indicator value or waveform screen).

DC 24V (± 10%) 13W

100V - 240V AC : PA-91 AC adapter is required (option)

Support for pulse input (A/B phase or A phase, differential square wave (RS-422 conformance) and voltage input ±5.2 V. Not only Time-Load but also Displacement-Load management is possible.

25,000 times/sec and 5,000 times/sec can be selected. (Resolution: 24bit)

This new function takes the hassle out of inputting numerical values during equivalent input calibration.

The calibration method uses the strain gauge transducer rated output (mV/V) and rated capacity that are recorded in TEDS memory.

※The unit only supports 4kbit.

The linearity of load measurements is improved by increasing the calibration points.

After actual load calibration and equivalent input calibration, input the linearization calibration.

The continuous judgment function is a judgment method that determines OK/NG by checking the value being measured against comparison values of "high limit, high high limit, low limit and low low limit."

Digital and graphical displays are also supported.

In continuous judgment mode, the displayed value can be fixed using a preset hold method.

Band judgment is a judgment method that continuously compares and judges measured values that change with time and displacement using the permissible band. Instead of high limit, low limit and other fixed values for continuous judgment, any curved line can be used for comparison.

Multi-zone judgment is a judgment method that determines whether or not the measured values are OK for the zones surrounded by the sections of allowable load and time or displacement.

Eight types of holds, namely, constant comparison, sampling, peak, bottom, peak to peak,average value, maximum/minimum and inflection point, can be designated as a means of OK/NG judgment. OK/NG is judged in a maximum of 5 zones for one process.Zone switching is also possible from an external input.

The combination judgment function is a judgment method that determines OK or not for one work by combining "Band judgment" and "Multi-zone judgment."

This enables detailed judgment even with complicated waveforms.

The D/A converter allows for analog output that corresponds to the unit indicator value.

Voltage output: 0 - ±10V

Current output: 4 - 20mA

The maximum voltage output can be set between ±1V and ±10V in 1V steps using the D/A max. voltage setting.

Standard feature: RS-232C, USB

RS-232C and USB cannot be used at the same time.

Options: Ethernet/IP™, CC-Link (planned)

As well as measurement data, setting information and judgment results can be saved in CSV format, making it easy to verify and utilize the results.

(Lists and waveform can be confirmed & statistics can be displayed)

Recording data format: CSV format

Recording file structure:

Header section (device numbers, measurement dates and times, sensor numbers, work numbers and other measurement data)

Data section (measurement data and comparison waveforms)

Save function for each folder linked to works (up to 16)

Newly equipped with overwrite mode. Up to 5000 items can be set (recommended: about 1000 items)

To ensure stable recording, use an SD/SDHC card with a capacity of 2GB or more.

For details, please refer to the Instructions for Use.

The data you care about can be checkd on the spot with the judgment result.

The function can investigate defects such as load cell deterioration and plastic deformation.

The input signal is displayed in strain amount unit (µST).

The disconnection point of the load cell can be checked in real time. If the possibility of an interruption is detected, the location of the possible interruption will be shown in red.

The status of control input/output signals on the back of the main unit can be checked.

Depending on the input signal, LOW (ON with yellow indicator) or HIGH (OFF) is shown.

Output can be turned ON/OFF for the connectors as desired.

Use this when checking output connections

A lineup of Ethernet/IP™ compatible model that can be directly connected to a PLC.

※The Ethernet/IP™ support model is a factory-installed option.

A lineup of CC-Link compatible models that can be directly connected to a PLC.

※the CC-Link support model is a factory-installed option.

The TD-9000T supports not only Japanese display but also English display. (Chinese and Korean will also be supported)

Acquisition of safety standards and environmental consideration, responding to globalization of customers.

- The display language can be switched between Japanese and English.

- In addition to Japanese, English, Chinese, and Korean manuals are also available.

- Compliant with CE and UL standards.

- Environmentally friendly design, compliant with European RoHS Directive and REACH Regulations

Equipped with a warning function that takes the user's point of view into consideration, making it easy to investigate the cause when a problem occurs.

The display language can be switched between Japanese and English. (Chinese and Korean will also be supported)

This appears when an invalid value has been set in a settings menu, for example.

Settings in menus that require warnings are shown when, for example, other settings must also be changed.

The TD-View is software that manages data measured by TD-9000T on a PC, and displays and statistically analyzes the data recorded on the SD/SDHC card on a personal computer. It shows its true ability in statistical process control. Not only individual measurement data (Time-Load, Time-Displacement, Displacement-Load), but also trends and histograms of OK/NG judgment points for the entire list and statistically calculated values (Data, OK/NG Count, Average, Maximum, Minimum, Variance, S.D, Fluct., Cp) are displayed.

In addition to saving the measurement data in CSV format, indicator value lists and graph data can be checked with a simple operation.

System Requirements

CPU: 2nd generation Intel® Core™ i5, 3.0 GHz or faster

OS: Windows 10

Memory: 4GB or more

HDD free space: 10GB or more

Screen resolution: 1024 x 768 pixels or higher

.Net Framework 4 Client Profile

Please contact us if you would like to download