What's TEDS

What is the calibration function?

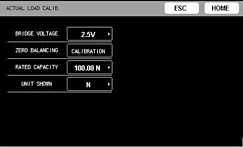

Connecting the unit with a strain gauge transducer and setting how the indicator values will be shown is called "calibration". The following three calibration methods can be used with the unit.

*Strain gauge type transducer: load cell, pressure transducer, platform scale, torque meter

| Actual Load Calibration | Equivalent input calibration | TEDS calibration | |

|---|---|---|---|

| Type of calibration |

This calibration method measures the values of actual loads on the strain gauge transducer. |

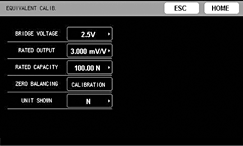

This calibration method does not depend on actual loads. It only requires the input of the strain gauge transducer rated output (mV/V) and the rated capacity (value you want shown). |

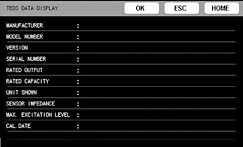

This calibration method uses the strain gauge transducer rated output (mV/V) and rated capacity that are recorded in TEDS memory. |

| monitor (TD-9000T) |

|

|

|

| calibration method | ①Prepare the reference weight ②Connect the load cell and indicator ③Place the reference weight on the load cell ④Record the value on the indicator ⑤Zero balancing ⑥Select EU ⑦Cal. Value Lock setting |

①Prepare a test report ②Connect the load cell and indicator ③Set minimum scale ④Register the output and rated capacity displayed in the test report ⑤Zero balancing ⑥Select EU ⑦Cal. Value Lock setting |

①Connect the load cell and indicator ②Automatic loading ③Zero balancing ④Cal. Value Lock setting |

| merit |

|

|

|

| important point |

|

|

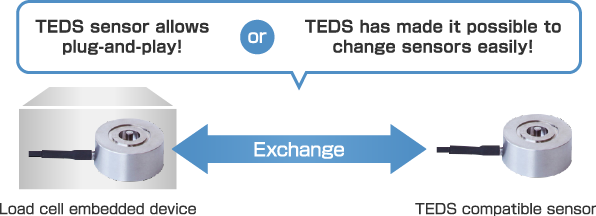

Plug & Play Solution from TEAC

TEAC load cells and digital indicators are compatible with TEDS (Transducer Electronic Data Sheet) which is a format defined within the cells and digital indicators are compatible with TEDS (Transducer Electronic Data Sheet) which is a format defined within the IEEE 1451.4 standard.

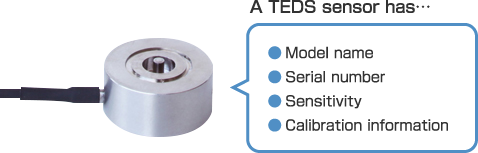

TEDS compatible sensors store specific information that contain the model name, serial number, sensitivity and calibration information in its memory.

This provides an automatic way to identify the sensor and program the indicator which eliminates any set up errors.

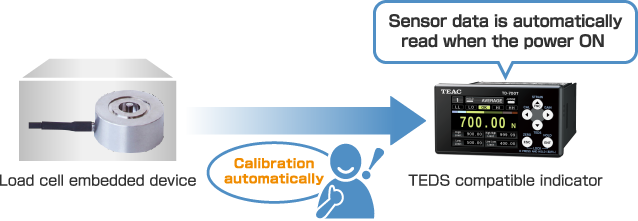

The information is automatically read from a TEDS sensor when power is applied.

TEDS Advantages;

- Connecting or changing sensors saves time.

- Eliminates confusing configuration steps.

- Eliminates the need to remember or have on hand calibration data since it is read from the sensor.

- Eliminates scaling and calibration errors.

- Gives a secure solution for you measurement.